YAKA, THE BAREFOOT NOVELTY

Discover YAKA, our new ultra-soft first-step model, which protects the foot while offering the sensation of walking barefoot.

Designed in our design office and tested on children's feet, YAKA respects the natural morphology of the foot and encourages its healthy development.

Thanks to its wide front and supple design, this is a shoe that protects... without constricting.

WILD STEPS

It's the trend to adopt for autumn!

Pom d'Api reinvents its classics with textured leathers and feline prints. Leopard in all its forms, faux fawn leather: details that mark every step with style.

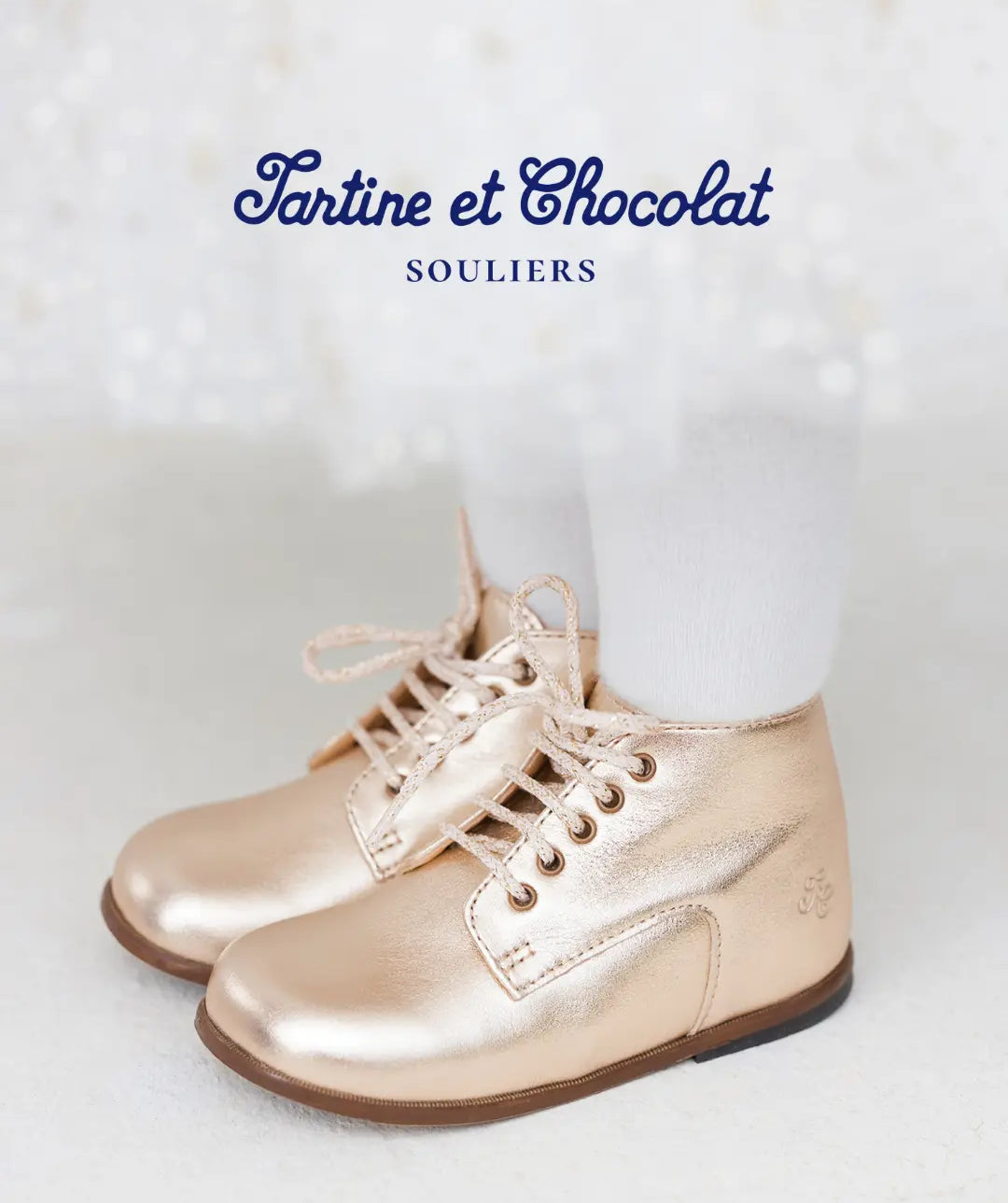

TARTINE ET CHOCOLAT SOULIERS

Pom d'Api presents its partnership with the prestigious French children's fashion brand, Tartine et Chocolat.

Discover the Autumn Winter 2025 collection, which is both modern and authentic, with clean lines and classic colors to suit every stage, from first step to junior.

OUR SHOPS

Discover the new collection in our Pom d'Api boutiques. Our sales consultants are on hand to answer your questions and help you choose the shoes best suited to your children.

Discover the Autumn Winter lookbook

Fall in Paris celebrates that Parisian je-ne-sais-quoi: Pom d'Api's own natural elegance, always a little offbeat, chic but never too wise.